Updated: January 2026 | Author: Justin (Manager at HF Umbrella)

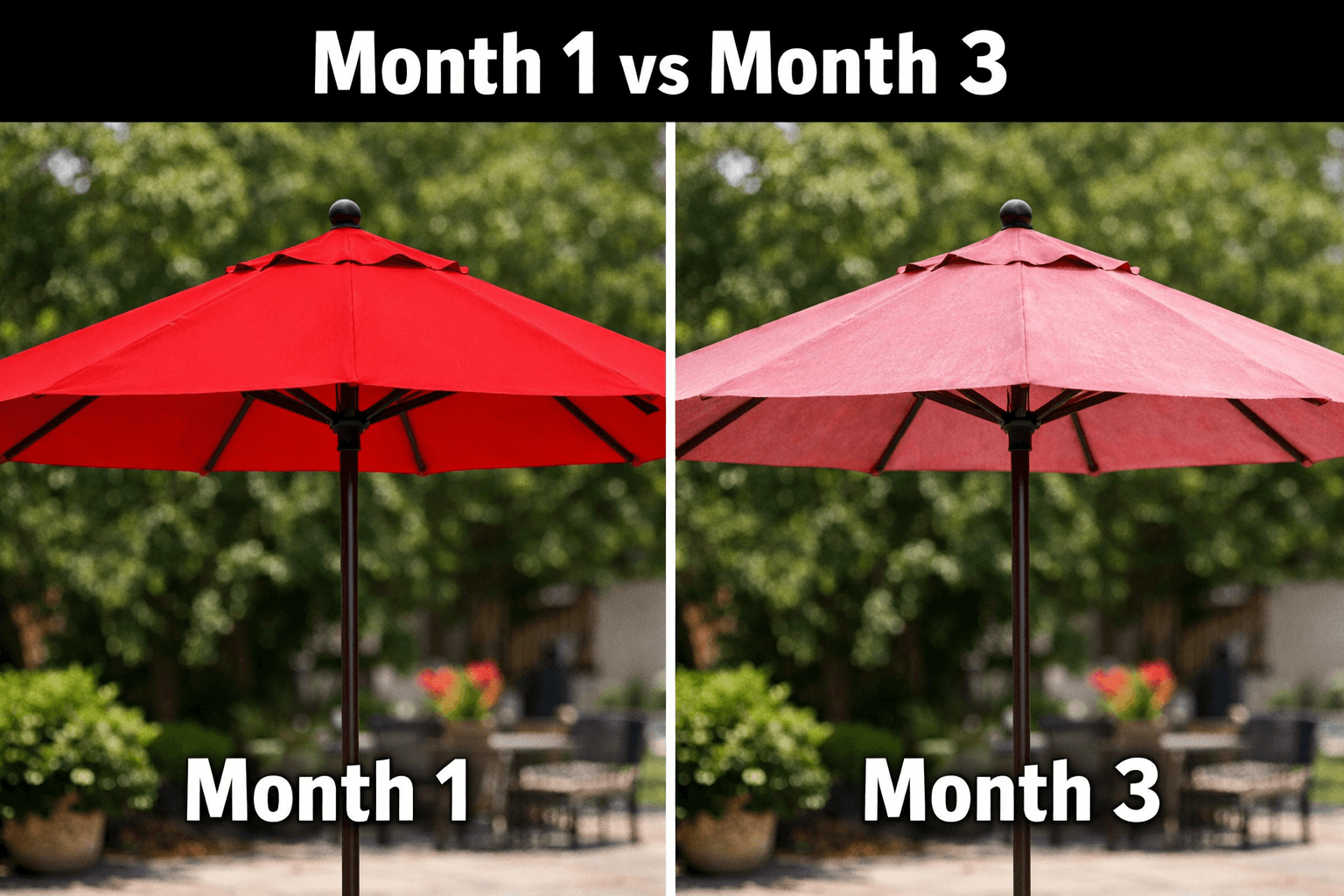

This is a disaster for your brand image. But it’s not bad luck; it’s bad chemistry.

Today, I’m taking you into our lab to explain Color Fastness, why cheap factories skip the “Fixing Agent,” and how HF Umbrella invented a process to stop your brand from fading.

Table of Contents

1. The Science: Fading vs. Migration (Know the Enemy)

Before we fix the problem, we must define it. There are two ways an umbrella loses its color:

- UV Fading (Lightfastness): The sun’s UV rays break down the chemical bonds in the dye. The color literally disintegrates.

- Color Migration (Transfer): This happens when excess dye isn’t “locked” into the fabric. When the umbrella is folded wet, the dark fabric touches the light fabric, and the color transfers (like a red sock in a white laundry load).

2. The Standard: Understanding ISO Grades 📊

How do you know if an umbrella will fade? You ask for the ISO 105-B02 Grade.

| Grade | Resistance | Typical Lifespan (Direct Sun) | Who Uses This? |

|---|---|---|---|

| Grade 3-4 | Low | 1-3 Months | Cheap giveaways (The $2 umbrella) |

| Grade 5-6 | Medium | 6-12 Months | Standard Retail Brands |

| Grade 7-8 | Excellent | 2+ Years | HF Umbrella Standard (Museum/Luxury) |

3. The Hidden Step: The “Fixing Agent” 🧪

Why are some umbrellas Grade 3 and others Grade 7? It comes down to the dyeing process.

When fabric is dyed, we must add a chemical called a Fixing Agent (固色剂). This acts like “glue” that bonds the dye molecule to the fabric fiber.

The Cheap Factory Trick: Fixing agents are expensive. They also require an extra washing step. Cheap factories skip this. The fabric looks fine when new, but the dye is just “sitting” on top, ready to fade or bleed at the first sign of rain or sun.

4. The Digital Challenge & HF’s “Double-Lock” Invention

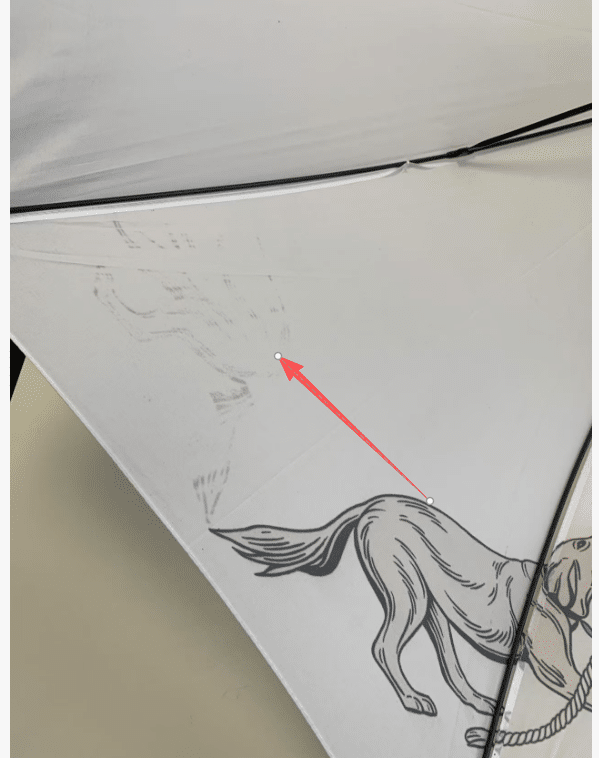

Digital Printing (used for complex art) is even harder to fix. Many factories print digital ink and ship it. This leads to sticky fabric and quick fading.

At HF Umbrella, we refused to accept this. We developed a proprietary Post-Processing Treatment.

The HF “Double-Lock” Process:

- High-Temp Steaming: After printing, we steam the fabric at 180°C. This opens the fibers and forces the ink deep inside the thread, not just on the surface.

- Industrial Washing: We wash the fabric to remove any “floating color” (excess ink).

- UV Inhibitor Bath: We apply a final coating that acts like sunscreen for the fabric.

The Result: You can take our Black & White umbrella, soak it in hot water, and fold it tight. Zero bleeding. Zero transfer.

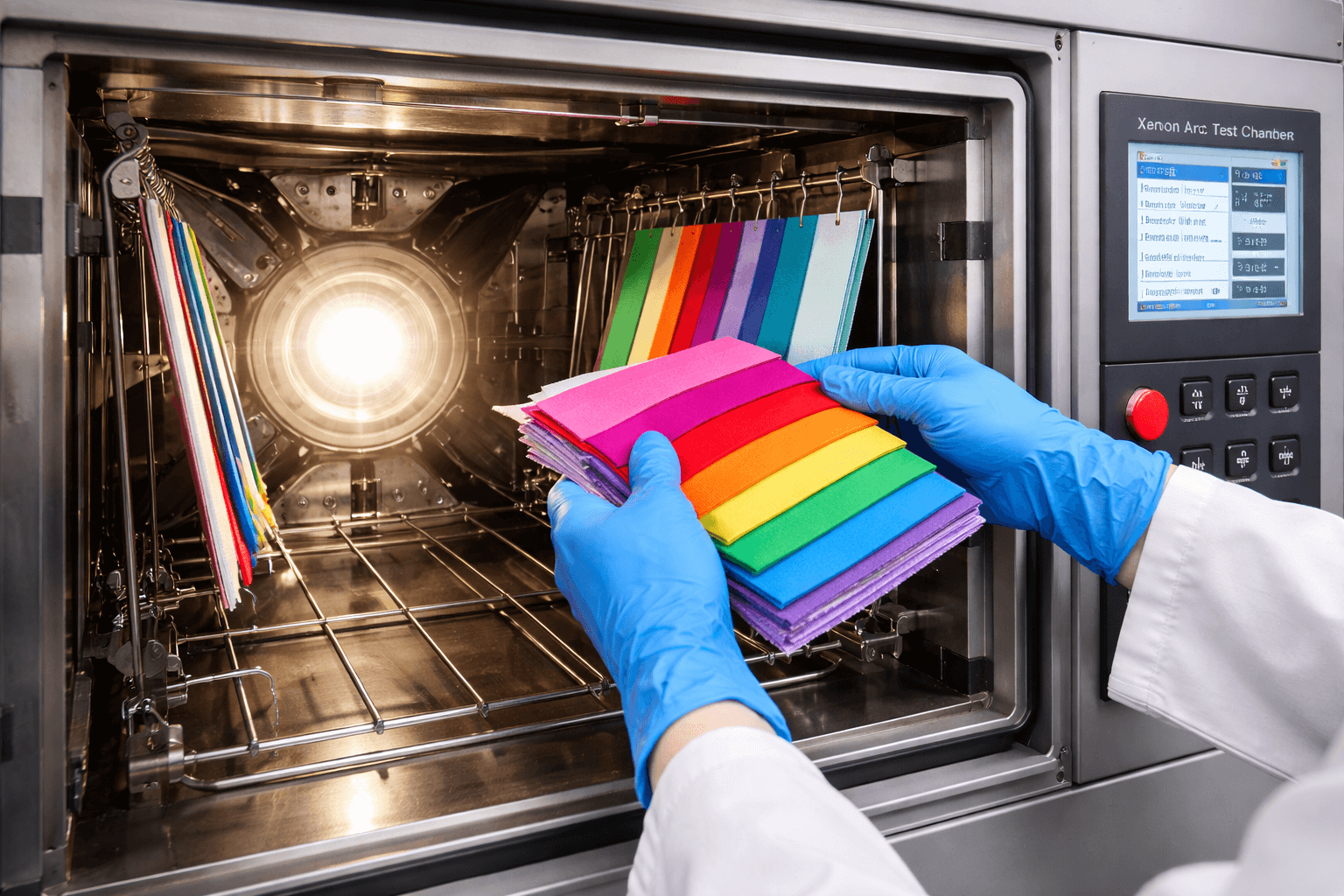

5. How We Verify: The Xenon Arc Test ☀️

We don’t guess; we test.

In our lab, we use a Xenon Arc Lamp. This machine simulates intense sunlight (100x stronger than natural sun). putting the fabric in this machine for 24 hours is like leaving it outside for 6 months.

If you are sourcing for a major brand, demand to see this test report. If the factory can’t provide it, they aren’t testing.

Protect Your Brand Colors

Don’t let your brand fade away. Work with a manufacturer that understands the chemistry of quality.

Send us your Pantone colors. We will send you fabric swatches that have passed the HF Double-Lock Process.