Table of Contents

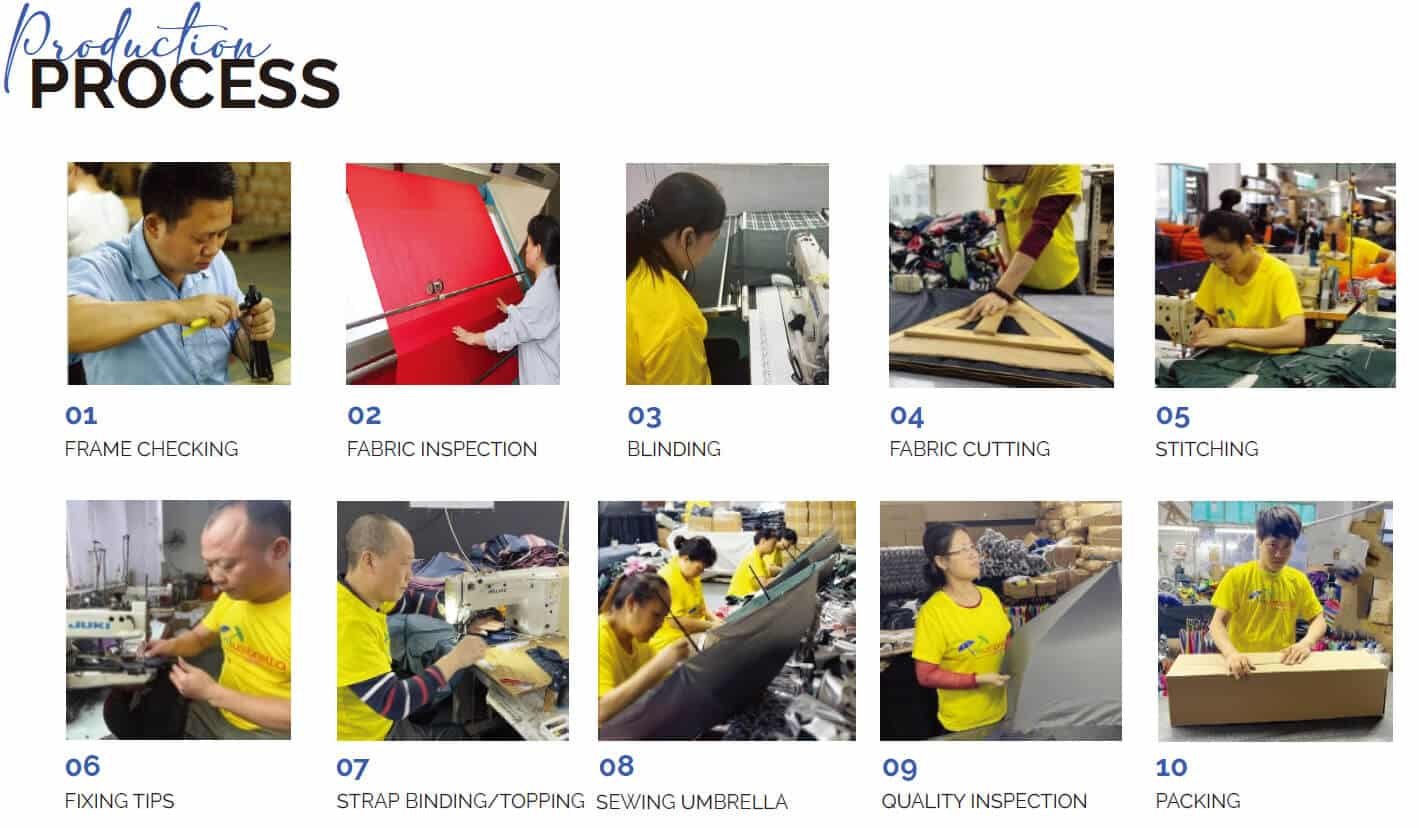

Step 1: The Cut (Precision Matters)

Everything starts with the fabric selection. Whether it’s RPET (recycled) or High-Density Pongee, precision is key.

- The Process: We stack hundreds of fabric layers and use a machine to slice them into “Gores” (the triangular panels).

- Justin’s Insight: “If the triangle cut is off by even 2mm, the canopy won’t sit tight on the frame. That’s why we use digital templates.”

Step 2: The Branding (Printing Your Logo)

Before sewing, we print. This is where your brand comes to life. Unlike buying stock umbrellas, custom manufacturing allows us to print flat panels before assembly.

- Screen Printing: For bold logos. We hand-mix the ink to match your Pantone (PMS) color.

- Digital Transfer: For complex artwork. We heat-press the ink into the fabric fibers so it won’t crack or fade.

Step 3: The Sewing (The Human Touch)

This is the heart of the factory. Our skilled workers stitch the triangular gores together to form the dome.

🚧 Quality Checkpoint:

The most critical spot is the “Rosette” (the cap at the very top). If this isn’t sealed correctly with a waterproof washer, water will leak down the shaft. We double-check every single top stitch.

Step 4: Assembly (Frame Meets Fabric)

Workers manually sew the canopy onto the ribs (skeleton). This requires nimble fingers and experience.

The HF Difference: Some budget factories use glue to attach the tips. We use double-thread stitching. It takes longer, but it ensures the tips never pop off during a storm.

Step 5: Quality Control (The Torture Test)

We don’t just look at the umbrella; we test it. Before packaging, your order goes through:

- The Light Box Test: Every canopy is opened over a bright light to check for tiny pinholes or fabric defects.

- Waterproofing: We subject random samples to high-pressure water spray.

- The Open/Close Test: We manually open and close the umbrella multiple times to ensure the runner moves smoothly.

See The Quality Yourself, Custom umbrella production

Reading about it is one thing. Holding it is another.

I invite you to request a Quality Sample Kit. See our stitching, feel the Pongee fabric, and test the fiberglass frame.